LEER Technologies Laser Cutting Services

Leer Laser Technologies offer advanced laser services for a range of commercial and manufacturing industries. We specialize in providing highly precise, premium quality laser cutting services that will benefit your bottom line.

Precision Parts for the Aerospace Industry

Increased efficiency without sacrificing cost can be achieved through Leer’s laser services.

The aerospace industry has become an increasingly widespread, commercial, and thus competitive industry in recent years. In order to maintain an advantage, many companies are searching for ways to make their particular sector more accessible to a wide range of consumers. Employing laser cutting technology means utilizing one of the highest levels of accuracy in the industry. Along with its incredibly efficient techniques, cutting with lasers also means higher quality and less waste.

Laser cutting technology has become an organic match with the aerospace industry because of its ability to work seamlessly with high-strength aluminum alloys while still maintaining a polished finish. Our state-of-the-art laser works with materials of varying shapes and sizes, making its ability to produce intricate parts efficiently which means a reduction in material waste as well as overall production cost without sacrificing quality.

Laser cutting, thanks to its ability to work with multiple materials in multiple ways, has brought with it a dramatic increase in both production, as well as cost efficiency within the aerospace industry. The aerospace industry operates on a much larger scale than most manufacturing enterprises and the resulting products need to withstand a great deal more pressure. The processes of manufacturing within the industry require even more precision and reliability. Our laser cutting technology sits at the vanguard of efficiency and durability, making it the perfect choice for your wide ranging needs.

Components for the Medical Industry

Our innovative and groundbreaking Trotec fiber laser offers new ways to create today’s critical medical devices.

Leer’s high tech cutting technology possesses the ability to cut and mark the metal alloys and polymers used to create the parts that make the medical industry a surging innovation in human health. Surgical instruments as well as implants and other related medical products require the kind of precision only made possible through the use of laser cutting technology. Our powerful laser increases the production of medical parts for devices such as stents and endoscopes, pacemaker components and other medical components.

Laser cutting technology offers many advantages within the medical manufacturing industry. Leer’s method of cutting delivers incredibly precise spot sizes, or tool widths, on components requiring high precision and high quality. Lasers can be employed to process a wide range of materials from stainless steel to titanium, the preferred alloy for implantation into the human body, and polymers used in the high-volume fabrication of microfluidic devices. Laser technology makes it possible for precision tubes to be cut which consistently proves to be a vital component in complex surgical operations as well as various other aspects of the industry.

The medical industry is one of the most vital sectors in the entire world and requires the most accurate and precise manufacturing possible. Producing parts with a laser ensures the production of the most highly efficient components used to both save lives, as well as drastically improve the human experience. In order for the evolution of the medical industry to continue, innovation and change in ideas must be cultivated. Leer’s laser technology means the processes used support those very foundational ideals. Allow our precision and efficiency to help your industry stay at the very peak of the health technology revolution.

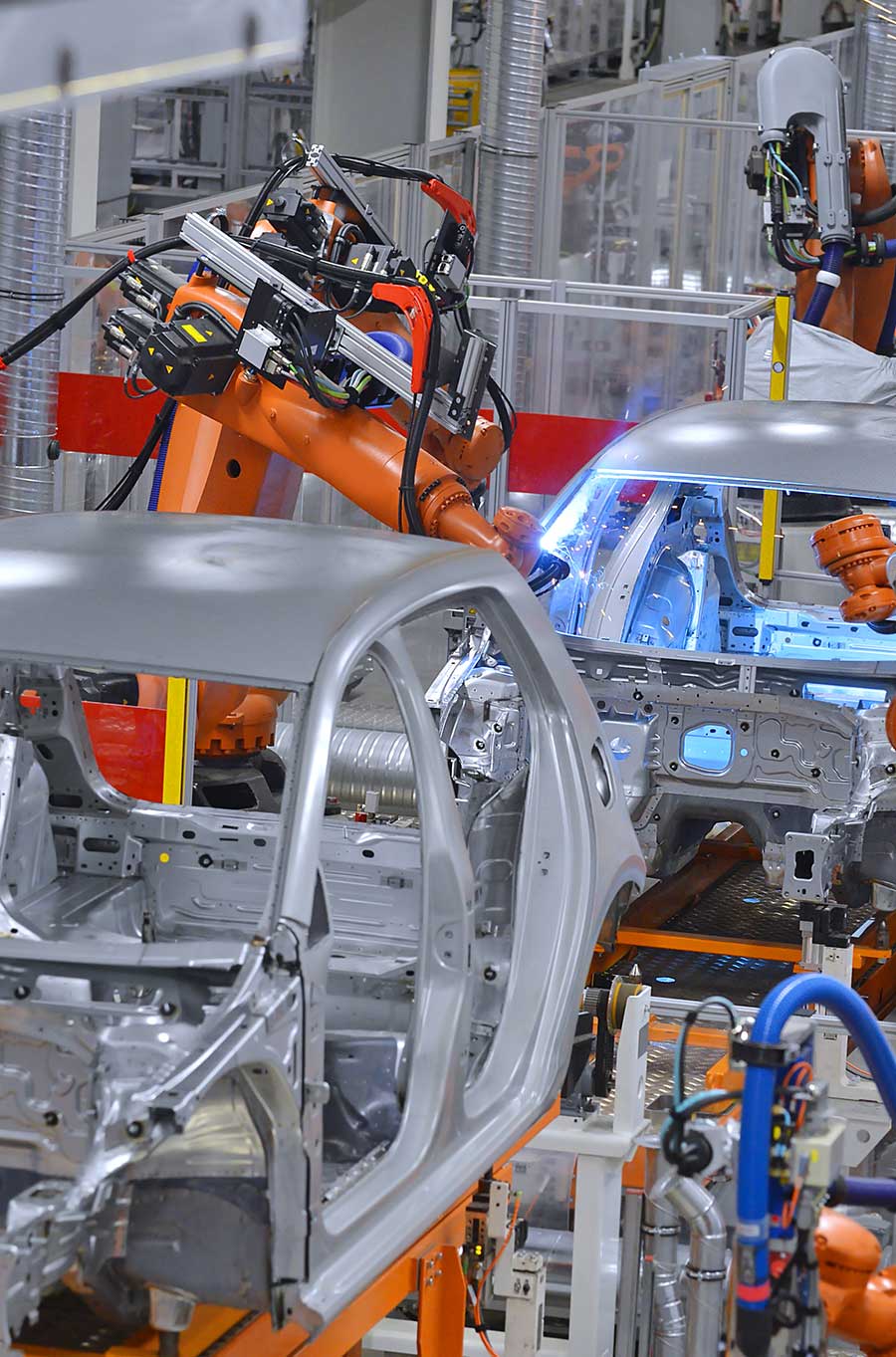

High Tech Part Production for the Automotive Industry

Our laser process employs the absolute quality cutting output as well as providing low heat input into the material and high processing speeds with a wide variety of components and materials.

What could be more pertinent in the world of automotive manufacturing than the term custom-made solutions? In today’s technologically advanced world, it is imperative that automotive competitors utilize the latest tech to produce the highest quality parts possible.

Laser technology improves the quality of a wide range of automotive production including carriage components, hydroformed parts, composite materials and even airbags. Leer’s fiber laser machine provides the kind of technology that has revolutionized the production of metal and auto industrial components. Apart from the technology itself, the use of laser cutting has also vastly improved the standards within the production of automotive parts. The seamless production processes as well as the lower cost efficient has allowed for new discoveries to be made within the industry. Within the automotive industry, there exists a countless variety of parts, pieces and people involved in the process of producing the right parts for the right function. Leer’s laser services, used in the production and manufacturing of automotive components, ensures the end product is reliable and safe as well as cost efficient.

The 21st century automobile has around 30,000 parts, meaning technology must be placed at the forefront in order to ensure reliable production. The importance of having reliable and efficient processes in place cannot be overstated and it is what will continue to drive innovation forward. These undeniable factors make cutting with our Trotec laser an invaluable part of the automotive industry. Let our laser technology be one of the many ways that your company contributes to the millions of cars on the road today.

Laser technologies assist in the manufacturing of many essential components. Surgical instruments, critical automotive components and highly detailed and functional materials are all part of Leer’s high quality standard.